Feature:

A simple feeding table with automatic movement is included.

Each process is easily controlled via a programming Logic Controller (PLC), touch screen and recipe control.

Accurate control of the film heating process is achieved through zones, allowing the use of different materials and thicknesses of the film roll.

Certain processes, such as film transport, forming, and trimming tables, are mechanized and pneumatically driven (by air).

A separate power supply converter cable is provided to power the machine worldwide.

The machine requires only a single operator for operation.

Maintenance is effortless and effective with easy-to-reach technology.

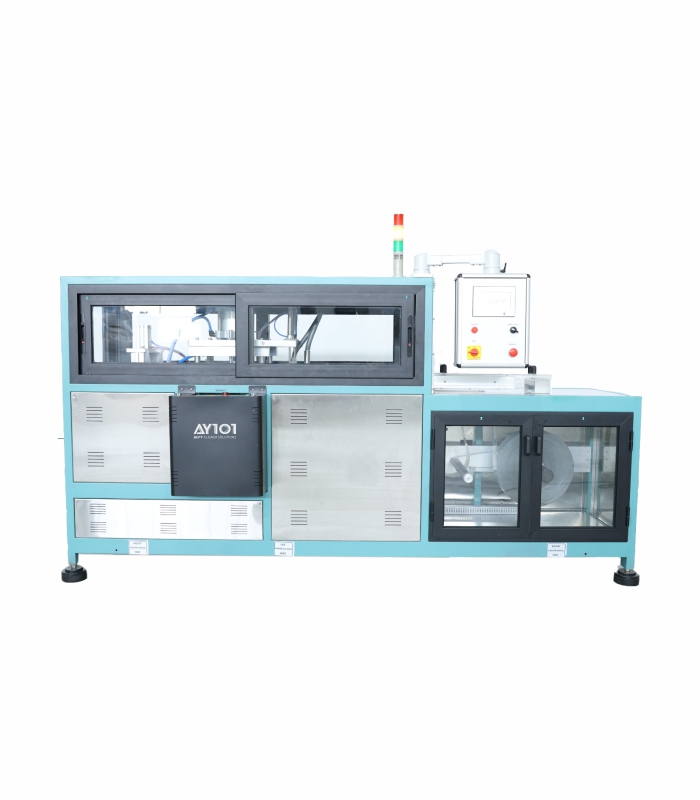

Fully automatic vacuum and pressure thermoforming machine.

Operation Processes

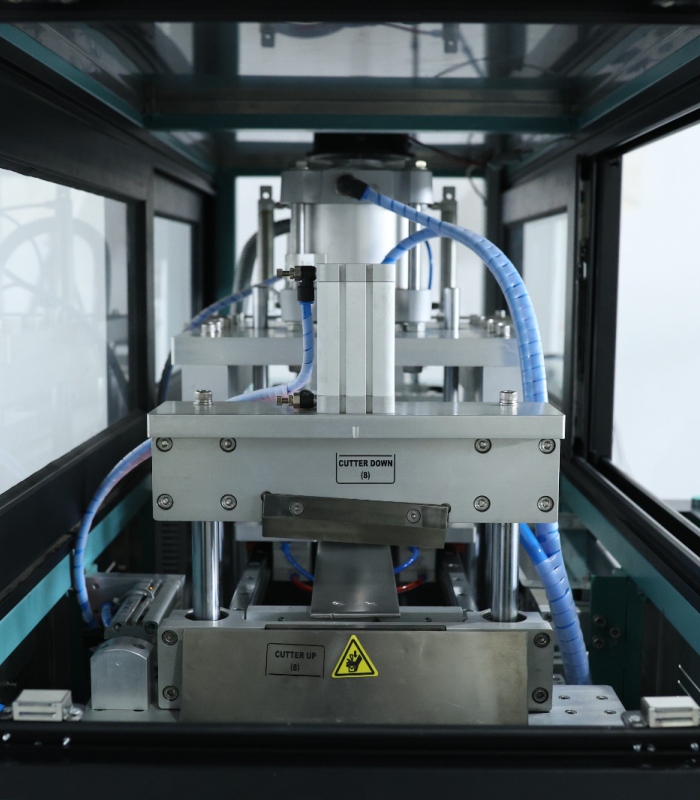

- Moulding

- In Feed Caraousel for 3D models

- Punching Station

- Ejection Station

Product Description

Body Material of the Machine: Stainless Steel , Powder coated.

Production Per Hour:

- Upto 360 units /h,

- 6 pair of Aligners in a 1 minute,

- 1 Pair of Aligners in 0.1 second (one tenth of a second)

Physical Dimentions: Approximate

- Weight – 540 Kgs,

- Height – 1680mm (5.51 foot).

With infeed Carousel: Frame

- Width – 1100mm (3.61 foot),

- Length – 2880mm (9.45 foot).

Power: Heating Power – 3kW,

Total Installed Power- 4kW.

Power Supply: 110v (1-ɸ) + G 50Hz.

Forming Film Roll:

- Max Diameter – 500mm,

- Max Thickness – 1.5mm,

- Max Width – 101mm,

- Concealed chamber to protect whole roll as well as film to prevent atmospheric effects like Humidity.

Forming Area: Max – 100 x 200mm

Forming height above film line: Max – 30mm

Forming Pressure: 8 Bars

Special Add-On Features: Vision systems, Laser Makers, and trimming units can be added.

Reviews

There are no reviews yet.